Why Oil-Water Separation Is Needed?

Estimated reading time: 5 minutes

In some ways, the components of a compressed air system are comparable to those of cars. There are some things cars must have to function, such as the engine. Then there are features, for example, seatbelts, that are not technically needed to run the car but that are still mandatory – not only because they make sense but also because they are required by law. Finally, some extras are just nice to have, such as heated seats.

In a compressed air system, you obviously need a compressor to keep the entire thing running. There are also some options that are not essential, but that will improve performance or efficiency, such as connectivity technology. And then there are features like oil-water separators. Adding them to a compressed air system that uses oil-injected compressors is not only dictated by common sense but also required by law in most countries.

Oil-water separators play an essential role in these systems. For all of their benefits, oil-injected compressors have a slight drawback: As a byproduct, they generate a condensate that includes traces of oil.

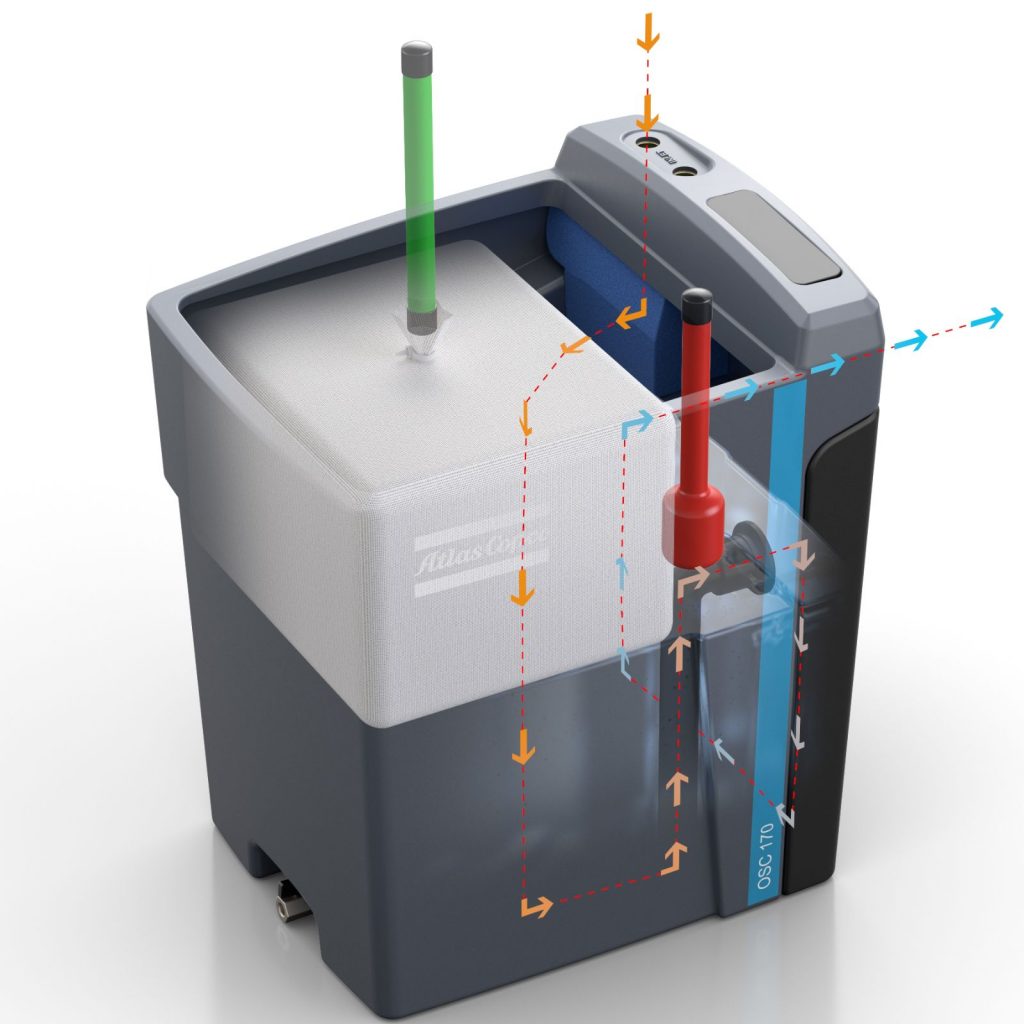

Fortunately, oil-water separators can fix this issue reasonably easily. Through different filters and filtration media, they are able to effectively remove the oil from the water so that it can then be safely and properly disposed of.

But why should you go through the trouble? Well, there are two main reasons.

Oil-water separation is the right thing to do

Allowing harmful substances to get into the groundwater is bad for the environment. Anybody who has followed oil spills in the news knows the consequences they can have for animals and plants.

One of the reasons why oil in groundwater is so bad is that it takes only a very small amount of oil to contaminate a lot of water. In the case of motor oil, for example, one unit of oil can contaminate one million units of water.

In addition to harming animals and plants, oil that gets into the groundwater also impacts our soil, rivers and lakes to the point where expensive cleanup efforts may have to be undertaken.

Concerning oil-water separation, that means that the more the condensate gets cleaned up, the better it is for all of us.

In this regard, the new OSC oil-water separator from Atlas Copco has set a new standard. Thanks to an ingenious triple-stage treatment system, it can filter out more types of oil from the condensate and achieve an outstanding water purity as low as 5 ppm at outlet.

Watch this video to know more about OSC oil-water separator

Oil-water separation is increasingly required by law

However, just like not every motorist wears a seatbelt even though it is clearly the safe and responsible thing to do, not every business will act responsibly on its own to protect the environment.

That brings us to the second reason: In most countries, this type of water treatment is mandated by increasingly stringent regulations – and violating them can result in heavy penalties.

In the UK, for example, a company can be fined up to £20,000 for improper condensate management. And in Germany, the Water Resources Acts mandates that a permit to discharge waste water may only be granted if the pollutant content in that waste water is kept as low as possible in accordance with state-of-the-art technologies.

Currently, the acceptable residual oil content is considered to be 20mg/l, but local authorities could mandate more stringent levels. This also means that these limits could be lowered at any time, which is why the OSC oil-water separator from Atlas Copco puts businesses on the safe side for the foreseeable future.

As an added bonus, the OSC series uses a new cartridge system that makes the units a lot easier and less messy to maintain than conventional oil-water separators.

That means, in the end, everybody wins: Operators, businesses and the environment.