Live Turboexpander Training Webinars

Expand your knowledge base and train your staff with live webinars with Atlas Copco Gas and Process turboexpander experts.

Speak with your local Aftermarket service representative, or contact Kyle DeBernardi at +1 805-680-8156, or kyle.debernardi@atlascopco.com to discuss the training program that’s best for your organization.

Live education session

Each turboexpander education session is presented and moderated by a live instructor. This allows you to engage with us for questions and comments instantly.

Built to fit your schedule

Our instructors are available to present in many different languages and time zones. Our team will work with you to find the most accommodating date and time to schedule your training session

Education no matter the location

Web-based training sessions enable your team to log in from anywhere – perfect for teams that are based in multiple locations

Parts Plan

Genuine Parts, delivered right where and when you need them.

Preventive Maintenance

Increase your compressor uptime with a preventive maintenance plan.

Fixed Price Services

Avoid financial surprises. Combine the expertise of factory-trained technicians with the quality of our Genuine Parts

Maximize your efficiency

Save on energy consumption and enjoy maximum uptime by analyzing, monitoring and optimizing your compressed air installation.

Training Overview

Course #101-EC, -ECM, -EGI:

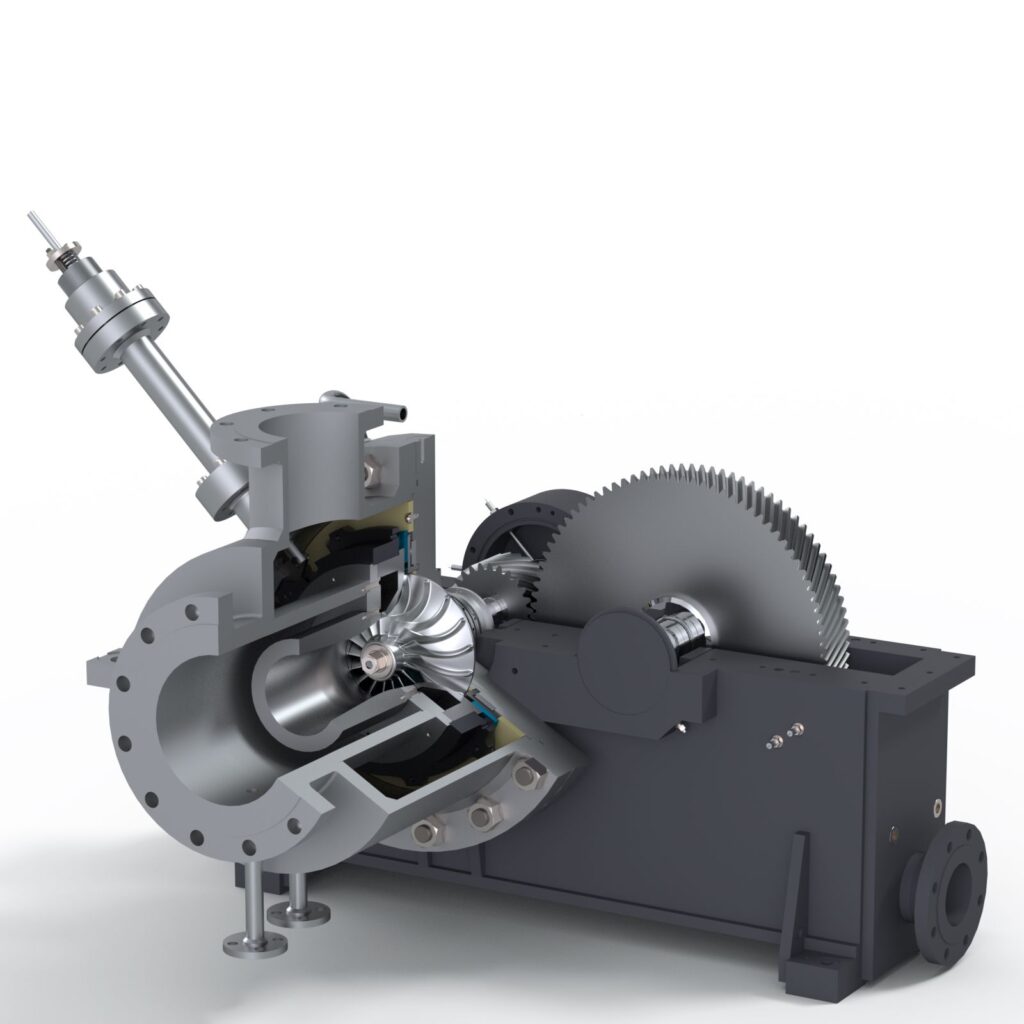

Turboexpander Components and Support Systems

8 hours. Designed for engineers, operators, and maintenance personnel.

This introduction to turboexpanders serves as a basic overview of the turboexpander skidded package to include a detailed examination of all turboexpander machine components internal to casings including the expander assembly, inlet guide vane assembly, expander and compressor impellers, shaft, bearings, compressor side assembly, and automatic thrust equalizer assembly. Turboexpander support systems are covered in extensive detail including machine skid components, process controls, instrumentation, machine monitoring and protection, and the Human Machine Interface (HMI).

Course 101-ECM immerses students in magnetic bearing technology inside of the machine including radial and axial magnetic bearings, position sensors, and auxiliary bearings as well as magnetic bearing control system topics including interconnection, wiring considerations, the magnetic bearing control cabinet, and operational modes.

Course 101-EGI includes comprehensive information on shaft sealing, gearbox and generator, and low speed coupling technologies. Electrical fundamentals related to power generators.

Course #201-EC, -ECM, -EGI:

Turboexpander Installation and Commissioning

8 hours. Designed for engineers, operators, and maintenance personnel.

All facets of turboexpander installation and commissioning are covered including skid installation and leveling, machine checks, lube oil and seal gas system installations, process flange alignment criteria, expander trip valve/compressor surge valve installation criteria, instrumentation calibration procedures, control system and PLC communication links. Topics such as lube oil selection, contamination, and dilution will be covered when applicable.

Course 201-ECM includes commissioning of magnetic bearing equipped turboexpanders. Topics include wiring inspections, installation of the control cabinet, initial rotor levitation, transfer functions, and field tuning.

Course 201-EGI includes skid grouting, low speed shaft alignment procedures, and soft blue check of gear tooth contact.

Course #301-EC/ECM, -EGI:

Turboexpander Start-up and Operations

4 hours. Designed for engineers and operators.

This course focuses on the safe and correct start up and shut down of the turboexpander and associated equipment with an emphasis on safety, machine performance and reliability. Topics include system purging, pressurization, cool down, start up, monitoring of operational parameters, tuning of skid and process control valves. Machine characteristics, expected performance, design operating conditions, off design operation are also discussed in detail. Operational concerns or “common pitfalls” based on 40 years of experience are explained and discussed extensively with examples, pictures, and prevention techniques.

Course 301-EGI includes specific details related to integrally geared turboexpanders including island mode and warm up procedures.

Course #401-EC/ECM, -EGI:

Turboexpander Maintenance and Servicing

4 hours. Designed for operators and maintenance personnel.

This course covers the required maintenance and servicing to uphold reliable and extend life of equipment. Common wear components, recommended spares, preventative maintenance plans, performance evaluations, and machine monitoring are discussed in detail. Common field services are discussed, with emphasis on monitoring and prevention.

Course 401-EGI includes specifics related to integrally geared turboexpanders.

Course #501-EC, -ECM, -EGI:

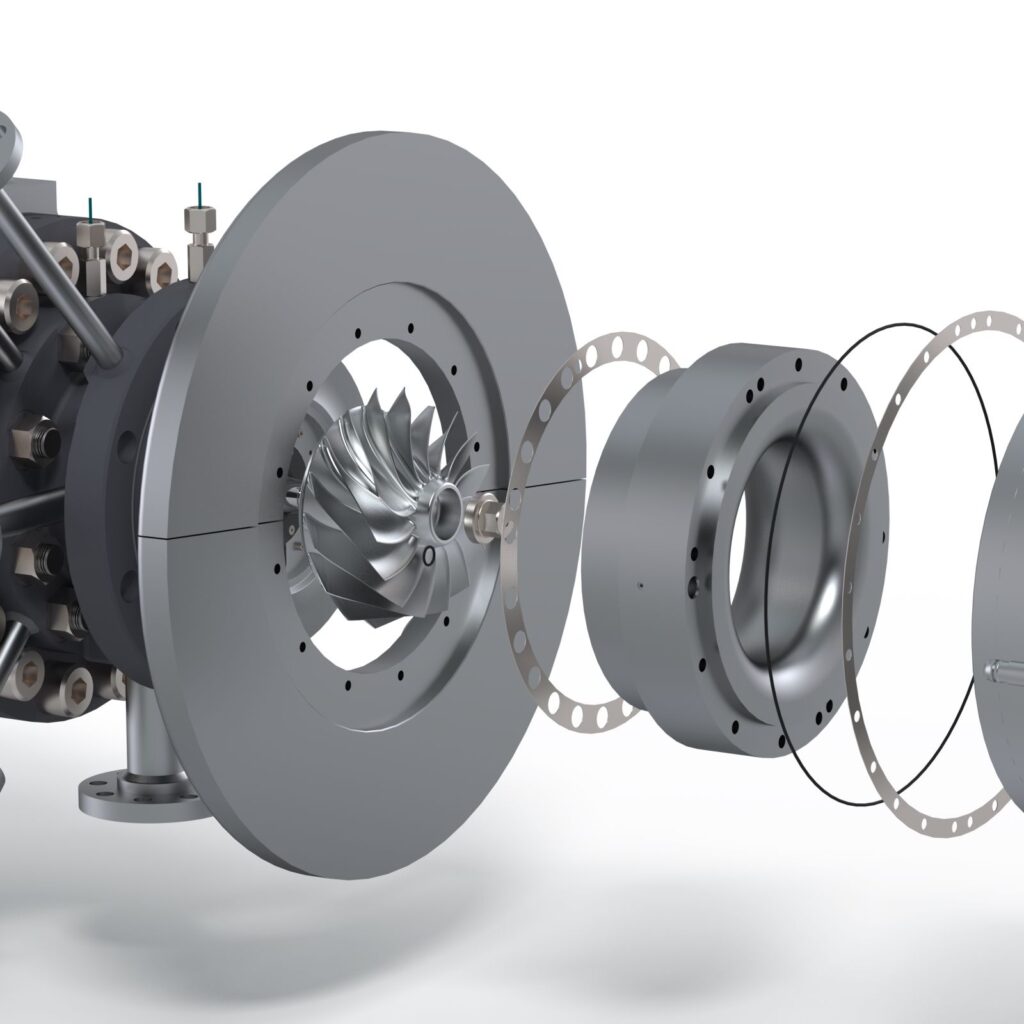

Turboexpander Disassembly and Assembly Procedures

8 hours. Designed for maintenance personnel.

Thorough review of pertinent documentation related to turboexpander disassembly and reassembly to include component identification, component inspection and acceptance/unacceptance criteria, critical clearance measurements, use of special tools, component cleaning and storage procedures, threaded fastener lubrication and thread locking recommendations and bolt torqueing procedures.

Course 501-ECM includes magnetic bearing, auxiliary bearing, and sensor shimming procedures. Includes magnetic bearing wire pass through and bearing cartridge installation and removal procedures.

Course 501-EGI includes high speed shaft seal installation details.

Terms

Purchase Orders should be issued in the name of Atlas Copco Mafi-Trench Company LLC, Santa Maria, California, USA, and should be based upon a final estimate for all costs involved.

All taxes, duties or fees imposed on Atlas Copco Mafi-Trench Company LLC or our personnel will be billed to the customer as direct expenses.

In the event Atlas Copco Mafi-Trench Company LLC’s performance of services is limited in any way, or is prevented in whole or in part from being delivered or concluded as ordered, by acts of God, fire, war, civil disorders, strikes, explosions, embargoes, accidents, floods, storms, shortages or failures of supply of fuel, power, raw materials, equipment containers or transportation, or by any rule, regulation, order or other action adopted or taken by any governmental authority or any other cause not reasonably within Atlas Copco Mafi-Trench Company LLC’s control whether or not specifically provided herein, Atlas Copco Mafi-Trench Company LLC shall be excused, discharged and released of performance to the extent such performance is limited or prevented without liability for damages of any kind.

All invoices are due and payable thirty (30) days after the invoice date. International training orders may require the establishment of a bank certified Letter of Credit rather than a purchase order.

Any dispute arising out of the services described, offered, delivered, or referenced in this document should be addressed to Atlas Copco Mafi-Trench Company LLC for prompt bi-lateral settlement. In the event an agreement cannot be reached, then legal recourse is available, but shall only be filed in the Superior Court of Santa Barbara County, the State of California, which maintains jurisdiction, and will be adjudicated in accordance with California law.

Atlas Copco Mafi-Trench Company LLC’s Terms and Conditions apply to all training services.